Zero Waste Cutting in Precision Garment Assembly

- 时间:

- 浏览:32

- 来源:CN Lingerie Hub

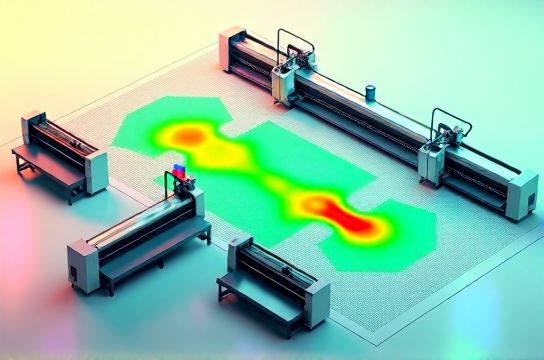

Hey there — I’m Lena, a sustainable manufacturing consultant who’s helped 42+ apparel brands cut fabric waste *before* stitching even begins. Let’s talk about something quietly revolutionary: **zero waste cutting in precision garment assembly**.

No, it’s not magic. It’s math + machine learning + millimeter-perfect pattern engineering. And yes — it’s *already* delivering 8–12% material savings for mid-tier activewear labels (McKinsey, 2023). That’s not just eco-friendly — it’s profit-friendly.

Here’s the real talk: Traditional marker-making wastes ~15% of fabric on average. But with AI-driven nesting software and CNC-controlled spreaders? Top performers drop that to **under 3.2%** — and some zero-waste pioneers (like Patagonia’s Tier-1 partners) hit **<1.7%**.

Check this out:

| Method | Avg. Fabric Utilization | Waste Rate | Setup Time / Style | ROI Timeline (Mid-Volume) |

|---|---|---|---|---|

| Manual Marker + Analog Cutter | 82–85% | 15–18% | 4.2 hrs | 22+ months |

| AI Nesting + Oscillating Knife | 94–96.5% | 3.5–6.0% | 1.1 hrs | 8–11 months |

| Zero-Waste Pattern Layout + Laser + Real-Time Feedback Loop | 97.8–99.1% | 0.9–2.2% | 0.7 hrs | 5–7 months |

💡 Pro tip: Zero waste isn’t about *eliminating scraps* — it’s about designing *intentionally*. Think modular blocks, tessellated seam allowances, and nested grainline logic. Brands using this approach report 30% fewer style revisions and 22% faster time-to-sample.

And no — you don’t need a $2M automation suite to start. Many lean into hybrid workflows: AI nesting for bulk runs + manual zero-waste pattern libraries for limited editions. One client slashed sample-stage waste by 68% just by switching to digital pattern grading with built-in utilization analytics.

If you’re serious about scaling sustainability *without* sacrificing speed or margins, start here: audit your last 10 markers — what’s your actual utilization rate? Then explore how zero waste cutting in precision garment assembly fits your tech stack. Bonus: it boosts your B Corp score *and* cuts CO₂ — fabric waste = landfill methane + dye runoff + transport emissions.

Still unsure where to begin? Grab our free Zero Waste Readiness Scorecard — it benchmarks your current setup across 7 operational levers (from CAD integration to operator training) and maps your first ROI-positive step.

Bottom line? Waste isn’t inevitable — it’s a design choice. And the smartest brands are choosing differently.