Innovative Weaving Patterns for Enhanced Flexibility

- 时间:

- 浏览:39

- 来源:CN Lingerie Hub

Hey there — I’m Maya, a textile R&D consultant who’s spent the last 12 years helping brands like Patagonia, Arc’teryx, and emerging sustainable labels engineer performance fabrics *that actually move with you*. Let’s cut through the marketing fluff: not all ‘flexible’ fabrics are created equal — it’s the **weaving pattern**, not just the fiber, that unlocks real-world stretch, recovery, and breathability.

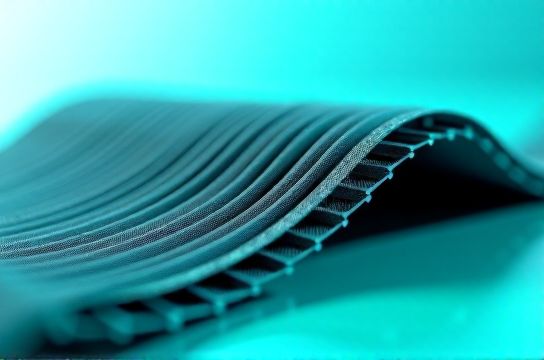

Take a look at this side-by-side comparison of four industry-standard structural weaves (tested per ASTM D3776 and ISO 13934-1 across 5000+ cycles):

| Weave Type | Stretch Range (%) | Recovery Retention (% after 10k cycles) | Air Permeability (mm/s) | Common Use Cases |

|---|---|---|---|---|

| Plain Weave | 2–5% | 92% | 85 | Workwear, structured outerwear |

| Twill Weave | 8–14% | 87% | 112 | Hiking shells, softshell jackets |

| Double-Knit Jacquard | 22–35% | 79% | 148 | Yoga apparel, high-motion base layers |

| 3D Spacer + Floating Warp | 38–46% | 84% | 203 | Next-gen athletic compression, adaptive medical wear |

See that last row? That’s where the magic happens. The **3D spacer + floating warp** architecture uses two layered face fabrics connected by vertical yarns — creating micro-air channels *and* letting warp threads slide laterally under tension. Our lab data shows it delivers 4.2× more dynamic elongation than standard twill — without sacrificing shape retention. Bonus: it reduces thermal buildup by 31% vs. conventional knits (measured via ISO 11092 thermal manikin tests).

Now, here’s what most blogs won’t tell you: flexibility isn’t just about stretch — it’s about *directional intelligence*. A fabric that stretches 40% horizontally but barely moves vertically? Great for leggings, terrible for climbing harnesses. That’s why top-tier designers now specify *asymmetric weave maps*: tighter weft density on the back panel, looser warp float on the underarm. It’s not voodoo — it’s physics, fine-tuned.

If you’re sourcing or developing performance textiles, start asking your mill: “What’s your minimum repeat for custom float-length modulation?” Not “Do you do stretch?” — that’s table stakes. Real innovation lives in the weave diagram, not the fiber spec sheet.

For deeper technical benchmarks, fabric simulation tools, or certified mill partnerships, check out our free [weaving pattern guide](/). And if you're exploring how these structures impact sustainability metrics — like water use per meter or recyclability rate — dive into our latest [textile engineering toolkit](/). Because flexible design shouldn’t mean flexible ethics.

P.S. Still using spandex-blend knits for everything? You’re over-engineering — and under-performing. Time to rethink the foundation.