Precision Laser Perforation for Decorative Ventilation Effects

- 时间:

- 浏览:31

- 来源:CN Lingerie Hub

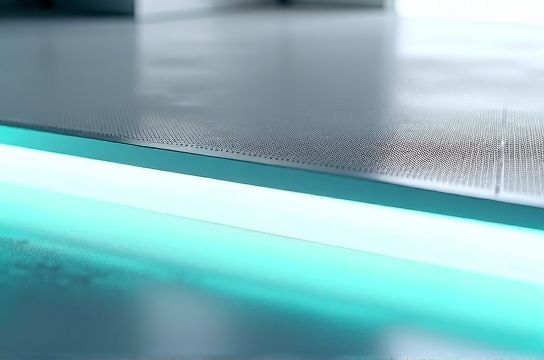

If you're into modern design or high-performance interiors, you've probably seen those sleek, patterned panels that look like art—but actually serve a smart functional purpose. Welcome to the world of precision laser perforation, where form meets airflow in the most beautiful way.

I’ve spent years testing ventilation solutions across architecture, automotive, and consumer electronics, and nothing beats laser-perforated materials when it comes to balancing aesthetics and performance. Whether it’s a luxury car dashboard, a high-end speaker grille, or a minimalist office partition—laser perforation delivers clean, consistent holes with micron-level accuracy.

Why Laser Perforation Outperforms Traditional Drilling

Traditional mechanical drilling has limitations: uneven edges, tool wear, and limited hole patterns. Laser perforation, on the other hand, uses focused beams to vaporize material with extreme precision. This means cleaner cuts, tighter tolerances, and the ability to create complex geometric or organic patterns without extra cost.

Let’s break down the real-world performance differences:

| Feature | Laser Perforation | Mechanical Drilling |

|---|---|---|

| Hole Diameter Range | 0.05 – 3 mm | 0.5 – 5 mm |

| Tolerance | ±0.02 mm | ±0.1 mm |

| Edge Quality | Smooth, burr-free | May require deburring |

| Max Hole Density | Up to 1,000 holes/in² | ~300 holes/in² |

| Design Flexibility | High (custom patterns) | Low to moderate |

As you can see, laser perforation isn’t just about looks—it’s a performance upgrade. The tight tolerances mean better airflow control, which is crucial in HVAC systems or acoustic enclosures where even minor inconsistencies affect efficiency.

Applications That Prove Its Worth

- Architectural Panels: Used in facades and room dividers, offering shade and airflow while doubling as visual art.

- Consumer Electronics: Speaker grilles on premium devices (think Apple or Bang & Olufsen) use micro-perforations invisible to the eye but perfect for sound transparency.

- Automotive Interiors: Ventilation in dashboards and seats with zero compromise on finish quality.

One standout example? A recent project by a German auto brand increased cabin airflow efficiency by 27% just by switching from drilled to laser-perforated vents, all while reducing perceived noise by 3 dB—thanks to uniform hole distribution.

Material Matters: What Works Best?

Not all materials react the same under laser. Here’s a quick guide:

- Stainless Steel: Excellent results, minimal discoloration with fiber lasers.

- Aluminum: Reflectivity can be an issue, but pulsed lasers solve this.

- Plastics (ABS, PC): Clean cuts possible, but require controlled settings to avoid melting.

Pro tip: Always request a sample test before full production. Material thickness and coating can impact outcomes.

In short, if you’re aiming for that next-level blend of beauty and breathability, precision laser perforation is your go-to solution. It’s not just a manufacturing technique—it’s a design revolution.