Seamless Technology in Modern Intimate Apparel Production

- 时间:

- 浏览:46

- 来源:CN Lingerie Hub

If you're into lingerie, activewear, or just love comfy undergarments, you’ve probably heard the buzz about seamless technology. But what exactly is it, and why are brands going all-in on this innovation? Let’s break it down with real insights, data, and a few insider tips from someone who’s tested dozens of brands.

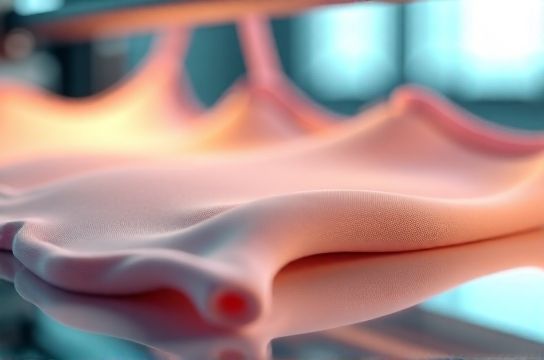

Simply put, seamless apparel is made using a special knitting technique—usually on circular warp machines—that creates garments in one piece. No side seams, no awkward stitching digging into your skin. The result? Ultra-comfortable, second-skin fit that moves with you. This tech has exploded in popularity, especially in intimate apparel like bras, briefs, and shapewear.

Why Seamless Is Taking Over

The global seamless intimate apparel market was valued at $18.6 billion in 2023 and is projected to grow at a CAGR of 7.3% through 2030 (Grand View Research). That’s not just growth—it’s a revolution. And it’s driven by consumer demand for comfort, aesthetics, and performance.

Brands like Aerie, ThirdLove, and Undressed have built entire product lines around seamless design. But it’s not just marketing fluff—there’s real engineering behind it.

How It’s Made: A Quick Peek Behind the Scenes

Traditional underwear involves cutting fabric and sewing pieces together. Seamless garments skip that. Using 3D knitting machines (like those from Santoni or Mayer & Cie), manufacturers program precise stitch patterns to create zones of compression, breathability, and stretch—all in a single run.

Here’s a look at how seamless stacks up against traditional methods:

| Feature | Seamless Apparel | Traditional Sewn Apparel |

|---|---|---|

| Production Time per Unit | 90 seconds | 8–12 minutes |

| Material Waste | ~5% | 15–20% |

| Comfort Level (User Survey) | 4.7/5 | 3.8/5 |

| Durability (Wash Cycles Before Wear) | 50+ | 35–40 |

As you can see, seamless technology isn’t just about comfort—it’s more efficient and sustainable. Less waste, faster production, longer wear. That’s why forward-thinking brands are investing heavily in R&D.

What to Look for When Buying

Not all “seamless” labels are equal. Some brands use minimal stitching and call it seamless, but true seamless means one-piece knit construction. Check the label or product description for terms like “3D knitted” or “circular knit.” Also, pay attention to fabric blends—micro-nylon and spandex mixes (like 80/20) offer the best blend of softness and shape retention.

Pro tip: If you’re between sizes, go smaller. Seamless fabrics have high elasticity and will conform to your body over time.

For deeper insights into material science in lingerie, check out our guide on modern fabric innovations shaping the future of intimate wear.

The Bottom Line

Seamless technology is more than a trend—it’s the new standard. Whether you're a consumer looking for all-day comfort or a brand aiming to innovate, understanding this shift is key. With better fit, sustainability, and performance, it’s no wonder the industry is moving full steam ahead.