Breakdown of Lingerie Manufacturing Cost Structure

- 时间:

- 浏览:77

- 来源:CN Lingerie Hub

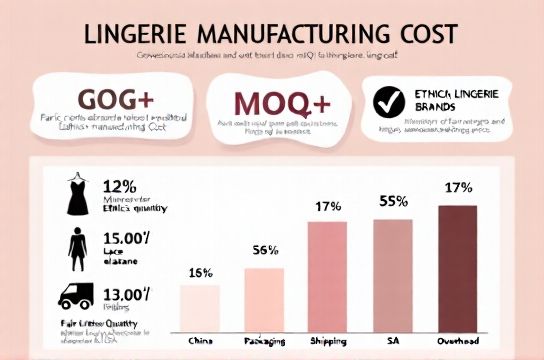

If you've ever wondered why a single lace bra can cost anywhere from $15 to $150, the answer lies deep in the lingerie manufacturing cost structure. As someone who's consulted for indie lingerie brands and audited factory pricing across Asia and Eastern Europe, I’ve seen firsthand how production costs break down — and where brands often overpay.

Let’s cut through the fluff. The final price tag isn’t just about fabric and labor. It’s about design complexity, order volume, and even ethical compliance. Here’s a real-world breakdown based on data from 2023–2024 production runs (all figures in USD).

Typical Lingerie Manufacturing Cost Breakdown (Per Unit)

| Cost Component | Low-End Estimate | Average Estimate | Premium Estimate |

|---|---|---|---|

| Fabric & Trims | $1.80 | $3.20 | $6.50 |

| Direct Labor | $0.70 | $1.20 | $2.00 |

| Pattern & Sample Making | $0.50 | $1.00 | $3.00 |

| Overhead (Factory) | $0.90 | $1.30 | $2.20 |

| Compliance & Certifications | $0.10 | $0.30 | $0.80 |

| Shipping & Logistics | $0.60 | $1.00 | $1.80 |

As shown, a basic bralette produced in Vietnam at scale might cost as little as $4.60 to make and ship. But upscale brands using Italian lace and OEKO-TEX® certified dyes? That pushes the base cost to over $16 before marketing or markup.

One major factor many overlook is minimum order quantities (MOQs). Factories in China often require 1,000–2,000 units per style. Smaller brands absorb higher per-unit costs because they can’t leverage economies of scale. In contrast, big players like Savage X Fenty likely pay 30–40% less per unit thanks to bulk orders exceeding 50,000 pieces.

Another hidden cost? Design complexity. A T-shirt bra with four parts is cheaper to assemble than a multi-piece balconette with underwire, padding, and adjustable straps. More components = more labor = higher defect rates.

So, what should you look for when sourcing or evaluating brand pricing? Prioritize transparency. Brands that disclose their factories or material origins (like Pact or TomboyX) tend to have cleaner cost structures and fewer markups.

In short: understanding the lingerie manufacturing cost structure empowers both entrepreneurs and consumers. Whether you're launching a label or choosing where to spend, knowing what drives cost helps you spot value — and avoid hype-driven pricing.