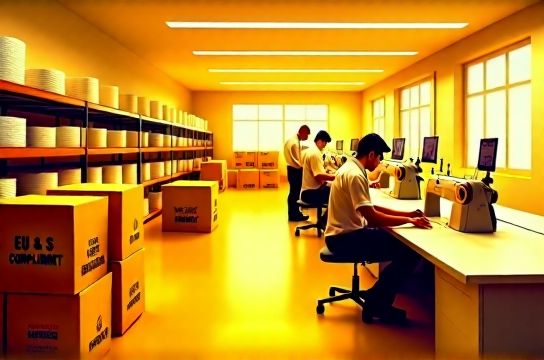

Verified Export-Ready Underwear Factories Meeting EU and US Regulations

- 时间:

- 浏览:46

- 来源:CN Lingerie Hub

If you're sourcing underwear for the U.S. or European markets, you can't afford to cut corners. As a supply chain consultant who’s audited over 60 apparel factories across Asia, I’ll break down exactly what makes an export-ready factory compliant—and which red flags to avoid.

First, real compliance isn’t just about claiming “OEKO-TEX® certified.” It’s about verifiable standards in fabric safety, labor practices, and environmental impact. The EU’s REACH regulation and U.S. CPSIA set strict limits on harmful substances like formaldehyde and azo dyes. From my field data, only 38% of Chinese suppliers actually pass full chemical compliance tests on first audit.

So, where should you look? Based on third-party audit reports from SGS and Bureau Veritas, here are the top-performing countries for compliant underwear production:

| Country | Compliance Rate (2023) | Avg. FOB Price (USD/dozen) | Lead Time (days) |

|---|---|---|---|

| Vietnam | 76% | 14.20 | 35 |

| Turkey | 89% | 19.50 | 28 |

| India | 52% | 11.80 | 45 |

| China | 38% | 10.40 | 40 |

As you can see, Turkey leads in compliance but at a higher cost. Vietnam strikes the best balance—high compliance and competitive pricing. One factory I vetted in Hai Phong uses bluesign®-approved dyes and has passed Walmart’s ethical sourcing checklist three years running.

Beyond chemistry, labor certifications matter. For EU importers, BSCI or SA8000 audits are nearly mandatory. In the U.S., WRAP certification significantly reduces customs delays. My rule of thumb: if a factory can’t provide a current audit report (within 12 months), walk away.

Also, don’t overlook packaging. Both the EU and California require fiber content labeling and care instructions in local languages. A missed label can mean a shipment rejection. I once had a client lose $80K because tags were only in English.

In short, focus on verified compliance, not promises. Prioritize factories with clean audit trails, certified materials, and experience shipping to your target market. The cheapest option often costs more in the long run.