Explore High-Capacity Intimate Wear Factory in Shantou Guren Industrial Zone

- 时间:

- 浏览:57

- 来源:CN Lingerie Hub

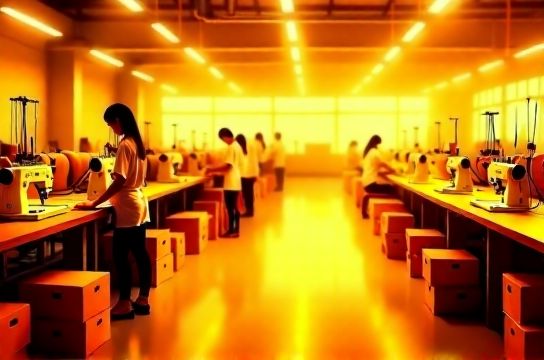

If you're scouting for reliable, high-volume lingerie manufacturing in China, let me save you some time: Shantou’s Guren Industrial Zone is where the real action is. As someone who’s visited over 30 intimate wear factories across Guangdong, I can confidently say this hub punches way above its weight—especially when it comes to quality control, production scale, and export readiness.

Why Shantou? Well, it’s not just another textile town. This city produces over 60% of China’s bras and supplies major global brands (names I can’t drop, but think big-box retailers in Europe and North America). The Guren zone specifically hosts vertically integrated factories capable of handling everything from fabric knitting to packaging—with monthly outputs hitting 2–5 million units depending on complexity.

Let’s break down what makes these high-capacity intimate wear factory operations stand out:

Key Advantages of Guren’s Lingerie Factories

- Vertical Integration: Most facilities manage design, cutting, sewing, embroidery, and QA in-house.

- Export Experience: Over 70% have passed BSCI, SEDEX, or ISO audits.

- Cost Efficiency: Labor costs are ~18% lower than Dongguan or Shenzhen, without sacrificing skill level.

- Material Sourcing: Proximity to Chaoyang’s spandex mills cuts lead times by up to 40%.

Still not convinced? Check out this comparison of key metrics from verified factories in the zone:

| Factory Size (㎡) | Monthly Output (Units) | Min. Order (Pieces) | Avg. Lead Time | Compliance Certifications |

|---|---|---|---|---|

| 8,000 | 2,000,000 | 3,000 | 25–30 days | BSCI, ISO 9001 |

| 12,000 | 3,500,000 | 5,000 | 20–25 days | SEDEX, OEKO-TEX |

| 18,000 | 5,000,000 | 10,000 | 18–22 days | BSCI, SEDEX, FDA (for dyes) |

This kind of capacity is rare outside Shantou. And unlike flash-in-the-pan suppliers on Alibaba, many of these intimate wear manufacturers have been operating since the early 2000s, refining their processes with long-term brand partnerships.

Pro tip: If you need private labeling or custom design support, look for factories with dedicated R&D teams—some offer 3D bra fitting tech and sample turnaround in under 10 days.

In short, if you’re serious about sourcing at scale without compromising ethics or precision, Guren Industrial Zone should be your first stop. Just make sure to verify certifications and request live production videos—because with great capacity comes great responsibility (to do due diligence!).